In the early stage of this research, the client clearly stated that they want a cable in “perfect” condition which could solve all the paints they had before. Therefore, a series of stringent requirements were put forward:

-3 meters transmission of high-definition signals, used for 4K/8K, stably transmit, high and low -temperature plasma disinfection;

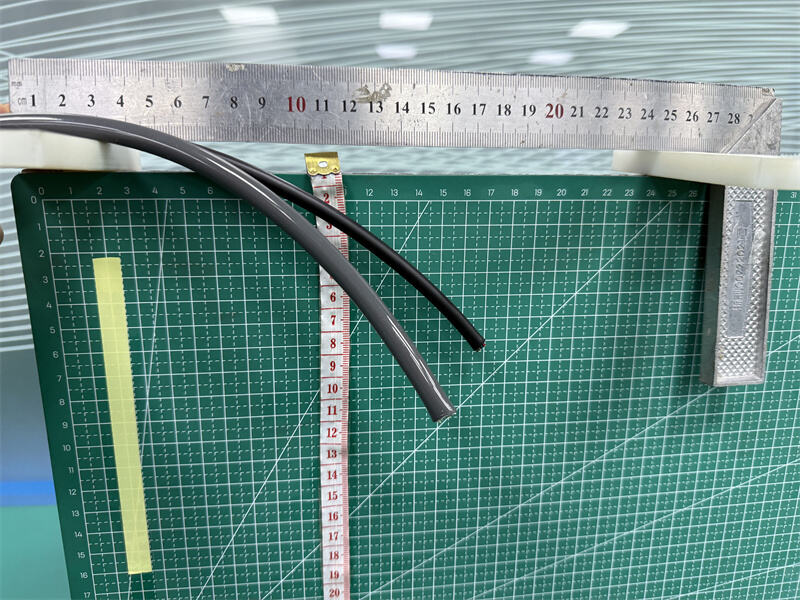

-the cable itself must be soft and elastic;

-super long useful life;

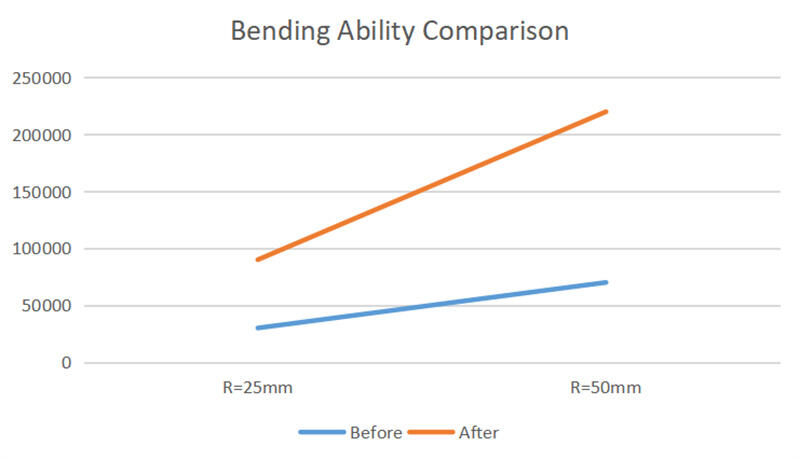

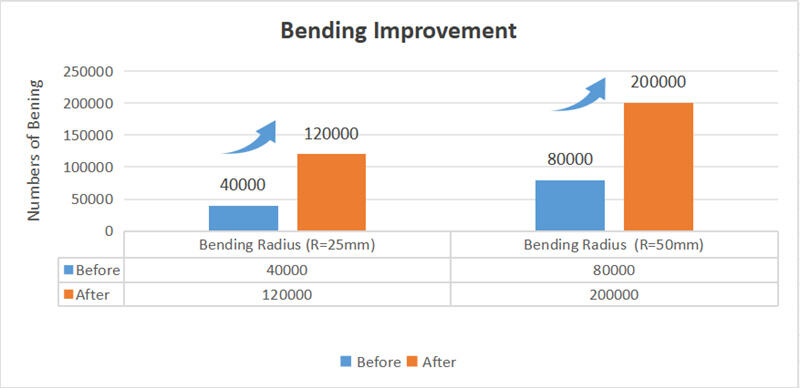

-the bending capacity must be more than doubled than present cable;

-the voltage resistance must be twice as high as before;

-the internal signal line near and far strings must reach -50dB;

-good hand feel.

...

In order to meet the customer’s requirement above, Hotten technology team bravely accept this challenge. Our advantage is the production of ultra-fine coaxial cables, using Teflon with low dielectric constant, low loss coefficient and high temperature resistance, and benefiting from Hotten’s research on conductors. We have carried out many repeated tests on the selection of materials. Finally, after trying more than a dozen times, a suitable conductor, insulation material, and silicone material were found. And trying many times for the equipment and production process until satisfied. Finally, the silicone handle cable that the client want is created.

The client was greatly surprised by the final cable product because of its design & sample produce time was only takes 2 months instead of planned 6 months. Meanwhile, when verifying the cable performance, it’s far exceeded than expectations.

See below details: